Lead Time Reduced from 6 Months to 10 Weeks

A customer in the security industry who was starting a new project needed to reduce their component production lead times but were using two materials — phosphor bronze and naval brass — which typically require upwards of six months to make it to production.

China Small Mechanical Parts had a solution. Read more...

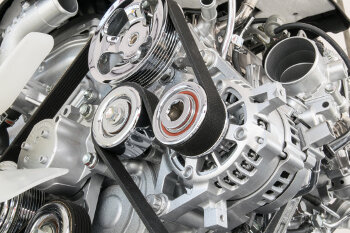

Performance Improvement AND Cost Reduction in Precision Automotive Parts

One of our automotive customers sought to reduce the overall noise level of their product in cars. China Small Mechanical Parts worked closely with the engineering staff to develop several versions of our precision automotive part to reduce vibration and noise. We interrupted the production line for 48 hours, made samples of each design and provided detailed analysis of production speeds and quality concerns of each design. After thorough testing, they were able to select a hollowed out version of the part, which not only reduced weight and noise, but also costs!

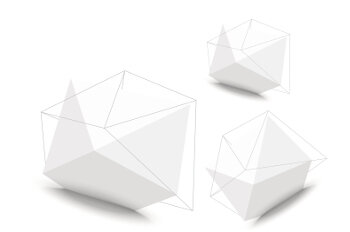

Double Take - Geometric Machined Parts

Typically knurls or hex configurations are used when overmolding our high precision components to insure a tight bond. Our customer needed a part that wouldn’t budge in the molding when put under torque pressure. Micro Precision recommended a rectangular shape which eliminated spinning in the plastic overmold.

Typical machining methods create rectangles from round stock using a mill and index rotation method, but that can be costly. Instead, we maximize the use of a polygon tool to create the shape from round stock and leave edges smoother than traditional milling. Then we stack two cutters on the polygon, so we can cut the thread on the part, complete on the machine, never stopping the spindle turning at over 10,000rpm’s!

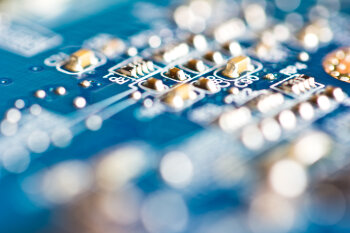

Pushing The Limits in Tight Tolerances

Precision deep hole drilling is often required when making a tight tolerance electronic connector that delivers ever increasing levels of performance. In many applications where inside diameter tolerances reach +/- .0003”, designers allow for drilling from both ends of part for ease of production. However, drilling from one side provides superior quality and faster productions speeds, so we developed a proven drilling system that machines very small diameter holes 25 times longer than the outside diameter of the part - all while holding tolerances of +/- .0001”.

Proprietary Processes in Micro Precision Machining

Our machinists are constantly devising new and better ways to meet the ever increasing demands for tighter tolerances. We assisted an aerospace customer in reducing costs and improving precision and performance by developing a special lapping and grinding process that provides extremely tight tolerances on highly polished finishes (4 microinch or better) with uniquely contoured machined shapes not typically produced by screw machines.

Machining By Feel

A thermostat device customer wanted a “precision feel” as parts of their threaded assembly engaged. They didn’t know how to quantify it – they just knew they wanted a smooth, effortless and "quality"" feel when they threaded together. After testing and running several trials, we reached the optimum “feel” and then documented that design at a substantial a cost savings!